We do a lot of product development. Sometimes it's just a variation of something we already make, but often it is something completely new. We identify a need or gap and see if we can fill it. In this blog we talk about how we created the SafeRocker+ canine rehabilitationand fitness equipment.

The starting point

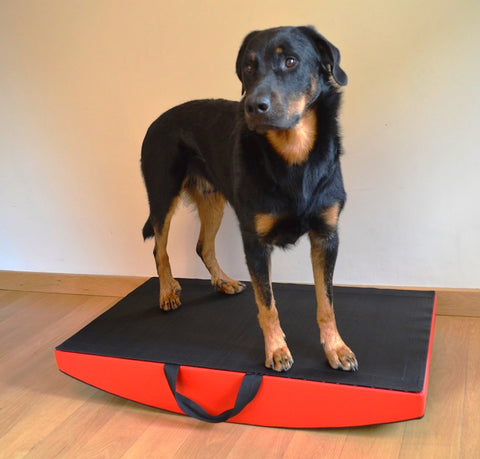

Our rehabilitation equipment, the SafeRocker+, came about as a result of seeing the kit that was already being used by therapists and concluding that a more useful and safer option was required. We were wanting to replace the centre fucrum rocker board that many vet physios had leaning against the wall gathering dust because it was difficult to use and the dogs generally didn't like it. The equipment came from the human physio world and really isn’t appropriate for animal use.

The primary thing to tackle was how unsteady a human rocker board is. Yes, you want a rocker to rock, but not in an uncontrollable way such that it crashes to one side hitting the floor with a loud bang. Try getting a dog back on something that does that. The rate of rock or wobble is also inappropriate for a dog undergoing post injury or post surgery rehabilitation.

So, how to do that? Eliminate the central fulcrum and make the whole base a curve. In the same way as a rocking horse has a smooth rocking action, this is what the SafeRocker+ needed.

OK, we've solved the aggressive motion, now what are we going to make the shape from and how big should it be? The size has to accommodate large dogs, but not take up too much space or make it difficult for therapists to access and control the patient. It couldn’t be too heavy as it had to be easily moved out the way and stored when not in use. Robustness for everyday use was a factor as was manufacturing cost.

Home Built

But before all that, a prototype was required to test whether the concept worked. And the cost of the prototype needed to be controlled in case it was a dead end idea. The first prototype was a real ‘Blue Peter’ job, though no washing up liquid bottles were involved 😊. The curve radius and size had to be co-ordinated along with the depth to ensure easy patient access. We wanted it to be over 100cm long for larger dogs and to have a useful but not too extreme curve to provide controllable wobble. Ultimately, it was a case of – that looks about right!

We could get foam cut easily, so a very high density crumb foam was cut to our requirements. A plywood board for the top was cut by local timber merchants, and a roll of non-slip matting bought and cut to size. The non-slip had to go top and base so it was secure on the floor but also for the patient standing on it. Then the whole lot was glued together on the dining room floor. Ta-da!

Testing, testing, testing

Now for the testing. Out it went to three different veterinary physios for several months to get their feedback on the concept. Was the level of rock right? How about size? Did it fill a gap in their equipment? Basically, was it useful, was it safe and did they like it?

We find that it’s not unusual for therapists to find ways of using kit we’ve developed that we hadn’t thought of and so was the case with the SafeRocker+. Why +, well, it was found to be almost equally useful upside down, ie curve side up so it didn’t rock. Slope and asymmetrical work, plus step work can all be done using this equipment. So not just a rocker.

And the outcome of the testing? A thumbs up from all three – yes, can we have one? So now we had to turn it into a finished item. The crumb foam was too heavy and despite it being high density, the base flattened with heavier dogs, reducing the wobble. The kit needed to be easy clean and look professional. Who was going to make it for us? We have a furniture making industry close by, and following many phone calls we found a small company willing to give it a go. The final version was created together using their skills and suggestions and our ideas and ‘must haves’. Polystyrene core, ply top, vinyl sides and some clever sewing to hold the non-slip surfaces and carry handles in place.

Not all trials are successful

We have looked at alternative ways of manufacture to bring the cost and hence price down, but nothing has been satisfactory. The SafeRocker+ has been in use for nearly six years now. One of our early adopters, the physio department at Southern Counties Veterinary Specialists, recently had their five year old SafeRocker+ refurbished and it looks as good as new, ready for another five years service.

Innovation and bringing new items into service is a key aspect of the business and one I love – possibly too much. I am a bit of a shiny light person – Ooo, let’s try to solve that problem….. 😊 We currently have three products under development and will be looking for people to trial the prototypes. Watch this space.